How Computer Circuit Boards Are Made

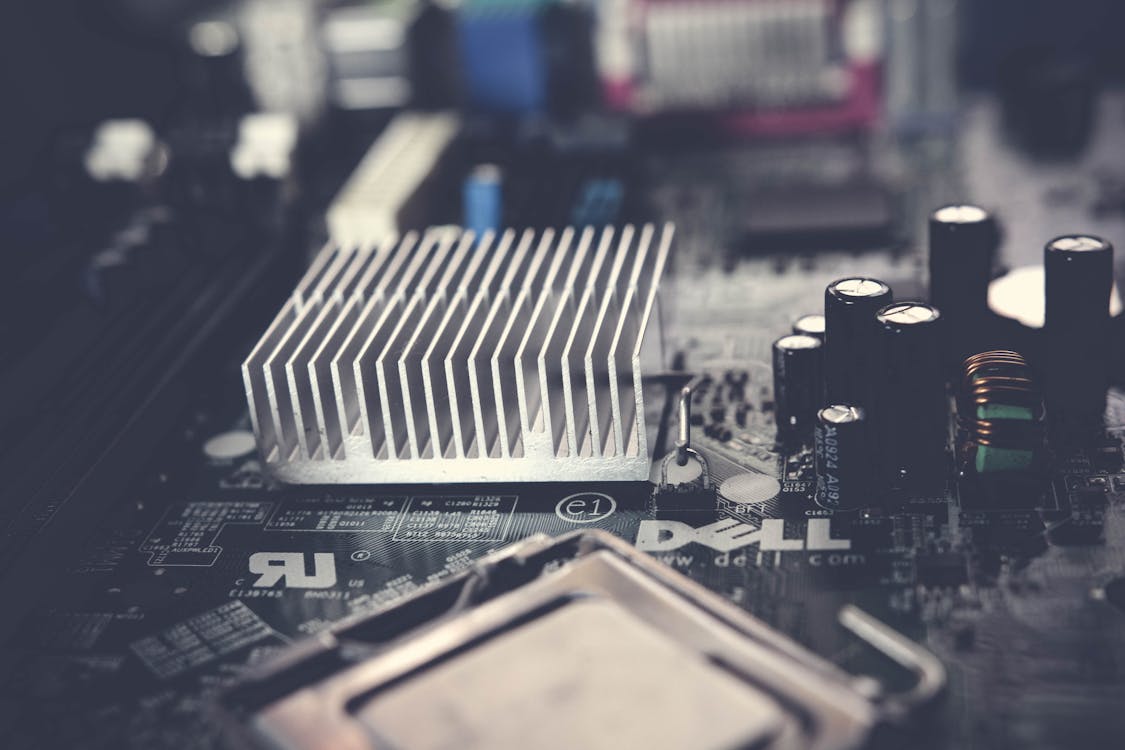

How do circuit boards work, Computer circuit boards contain a complex array of components (both surface mounted devices and through-hole devices) that are soldered together to provide specific functionality. A circuit board is the basic building block for most electronic devices like desktop computers, mobile phones and cordless printers. It provides the mountings for the devices, and the paths between them that are governed by the logic of the device's microprocessor chips. The chips contain miniaturized transistors, capacitors and resistors that manipulate, store and release electricity in varying patterns that ultimately allow visual patterns to be displayed on a screen (that you recognize as words, an image or a website), audio patterns to vibrate your speakers and be heard by you (music), droplets of ink to be squirted on a page by the printer and so forth.

The first circuit boards were wired point-to-point, with the leads of the components being connected to insulated rails or pins on a chassis. The chassis was often a sheet metal frame or pan with a wooden bottom and the connections were made by soldering, using jumper wires, crimp connector lugs on wire connector studs, or in a few cases, with a mechanical connection, such as a screw terminal. The circuit boards were large, bulky and heavy, making them expensive to produce.

Inventor Charles Ducas's 1927 patent used a stencil to print wires onto a bare board with conductive ink, placing an electronic path right on the insulating surface. This was the genesis of the modern printed circuit board, also known as a PCB.

Today's computer circuit boards are produced either additively or subtractively. The additive method employs the use of a mask to expose or not expose areas on a bare laminate. A copper layer is then plated over the exposed areas, making them capable of bonding with metallic ions. The excess copper is then removed, exposing the pattern that was previously hidden by the mask. The pattern is then etched to remove the remaining resin and glass fibers, leaving behind only the copper layers and the traces of metal that connect each component pin to its neighbors on the board.

After the pattern is etched, the bare laminate can be coated with an epoxy or other protective material. A legend is then printed on one or both sides of the PCB that contains the component designators, switch settings and test points and other information helpful to assembling, testing and using the board.

In addition to the copper traces, a multi-layer computer circuit board has insulating layers of fiberglass or epoxy as well as a solder mask. A metallurgical process, usually electrochemical or bioleaching, is used to recover the metals from the board for recycling. The electrochemical process is cheaper and quicker than the hydrometallurgical method. It is more environmentally friendly than traditional methods such as smelting and refining, which require high temperatures and energy consumption. Ideally, the best way to recycle a circuit board is to separate the components for recycling.